Getting something back from carbon dioxide

Carbon dioxide is often considered the big bad wolf of greenhouse gases, a major cause of climate change and global warming according to specialists. But what if it could be used to produce energy and mitigate some of its impact?

Two Swiss projects are considering just that. One, private, is looking at how to suck up CO2 with its own version of a giant vacuum cleaner, while the other, public, wants to use it to produce methane thanks to small minerals known as zeolites.

At Zurich-based Climeworks, the aim has been for the past five years to develop a technology to continuously extract atmospheric CO2 that can then be used to produce synthetic fuels or applied for other purposes.

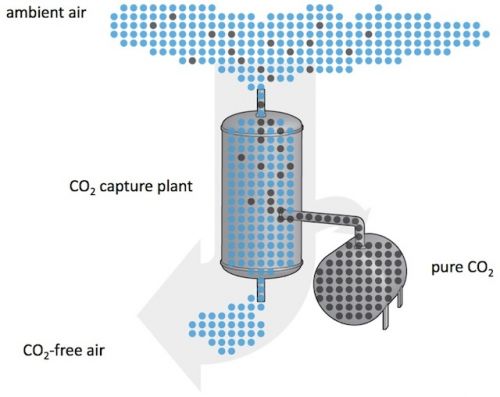

Carbon dioxide is collected by passing air through a specially-treated cellulose filter placed inside an extractor unit. Once it has reached its maximum capacity, the filter is heated using waste energy or renewable power to release extremely pure CO2.

“We aim to de-carbonise some parts of the transportation sector such as aviation, which accounts for single-digit global CO2 emissions,” said Christoph Gebald, one of the company’s founders.

Aviation is responsible for around 3.5% of anthropogenic (man-made) climate change and has a 13% share of all the transport sector, according to the United Nations’ Intergovernmental Panel on Climate Change.

So far, Climeworks has been testing a so-called direct-air capture unit that can collect one ton per year of CO2, filtering around two million cubic metres of air, to demonstrate the validity of its approach.

Synthetic fuels

The result has been sufficiently interesting to attract the attention of German carmaker Audi, which sees the technology as one potential element of its strategy to develop vehicles running on synthetic fuels.

“What they need is a sustainable carbon dioxide source,” pointed out Gebald. “It can be either biogenic or atmospheric.”

However the first source, which results from combustion or decomposition of biologically-based material, is insufficient to meet the requirements of a single carmaker according to the young entrepreneur.

A test plant is now on the cards to see how the technology can be scaled up to provide enough CO2 for Audi’s production of synthetic fuels at its e-gas facility in Germany.

The technology is also on the fast-track to wider exposure. The company is one of 11 finalists in the Virgin Earth Challenge, a competition with a $25 million prize for the development of “an environmentally sustainable and economically viable way to remove greenhouse gases from the atmosphere.”

Challenges

Extracting and purifying CO2 is just one step of the process towards producing synthetic fuels.

In theory, producing methane that could be injected into the natural gas network by combining carbon dioxide and hydrogen with a boost from an outside source of – ideally renewable – energy to kickstart the reaction is relatively straightforward, with water as a by-product. The process is known as the Sabatier reaction and was discovered early in the 20th century.

Doing this economically and quickly is a challenge though, as is separating the water molecules from the methane. Adding a catalyst, an element that speeds up the process, can help overcome some of the hurdles, but also carries the risk of producing toxic carbon monoxide (CO) and often low yields.

At the Federal Laboratories for Materials Science and Technology (Empa) near Zurich, researchers have been looking for a process that works at low temperatures and turned to zeolites, which are microporous minerals.

“Nickel-coated zeolites absorb the water generated by the process, almost no CO is produced and the gas at the end is methane,” said Andreas Borgschulte, the lead scientist on the project.

The result is far from perfect though. “It’s still experimental and the amount of water a zeolite can absorb is limited, so it has to be ‘dried out’, regenerated,” explained the researcher.

No silver bullets

Little more than a chemical reaction in a laboratory reactor at this stage, turning it into an viable process will require more work. While zeolites are easy for scientists to produce in small quantities, it would be necessary to find a cheaper way of producing them on an industrial scale.

There are also engineering challenges according to Borgschulte, such as upsizing the reactor, managing large volumes of gas, power and capital requirements. And to be carbon neutral, the process would ideally rely on CO2 from biomass, not from fossil fuels.

“Gas prices are very low, so it would be hard to compete,” Borgschulte said. “Synthetic gas would be more expensive by a factor of five.”

Pricing is also the challenge for Climeworks. Scrubbing CO2 from the air can cost up to CHF600 per ton according to one study from Zurich’s Federal Institute of Technology.

The company hopes to reduce this to around CHF100 in the coming years, making its system more competitive. Its method is headed in that direction as the heat needed to recover the collected carbon dioxide has a much lower temperature – less than 100 degrees Celsius – than that used for other systems, which traditionally operate above the 300-degree mark.

Even if these technologies reach full maturity and become part of the mainstream, no one expects them to solve the problem of global warming.

“It’s not a silver bullet, and shouldn’t be considered as such but only as part of a portfolio of technologies that will become important in the medium to long-term,” said Gebald.

Carbon dioxide plays a major role in shaping climate and temperatures. Under ideal circumstances, CO2 is part of the so-called carbon cycle, a neutral process over the longer term. But humans have upset that cycle by using fossil fuels and cutting trees and research has shown that higher CO2 concentrations tend to warm to warm the Earth’s surface.

Carbon dioxide is not the only greenhouse gas, and others such as methane, nitrous oxide and different aerosols also make their way into the atmosphere.

Relatively speaking though they are far less important than carbon dioxide, whose emissions are huge compared to other agents. Its effects can be seen in the atmosphere for much longer as well. Of the total amount emitted now, scientists reckon that 20% will still be in the atmosphere in 1,000 years’ time.

Direct air capture (DAC) concerns technologies that can capture large amounts of CO2 from atmospheric air. The other main technological option for CO2 capture is point-source carbon capture and storage (CCS), which used on flue stacks that emit higher concentrations of carbon dioxide.

The obstacle for DAC is the cost-factor, which needs to drop to be competitive with CCS. According to some studies, the cost is up to ten times higher for DAC. The technology is still largely experimental and some way off from full-scale industrial application, although CCS itself has not been widely implemented so far.

Besides Climeworks, a number of companies are working on DAC, including Carbon Engineering, Global Thermostat, Coaway and Terraleaf to name a few. Many of these firms are start-ups building on earlier academic research. Scientists at Columbia University, the Georgia Institute of Technology, and the University of Southern California are also carrying out further research.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here. Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.