When Swiss quality is a barrier to success abroad

Despite a demand for innovative products, emerging markets like India are not prepared to pay a premium for Swiss quality. This presents a challenge for Swiss enterprises who want to stay competitive but without risking their hard-earned reputation for perfectionism.

A tourist coach pulls up at the pretty Swiss town of Arbon on the shores of Lake Constance and disgorges its foreign passengers, who then proceed to do touristy things like taking photos and eating ice cream. Only, they are not ordinary tourists but top executives from Indian public sector companies who are on a study tour to Switzerland to learn about technological innovation.

After the photos and ice cream, the coach drops the Indian executives at Trunz Water Systems, a typical example of an innovative Swiss small and medium enterprise (SME). Trunz specialises in manufacturing solar-powered water purification systems and has been doing business in India for many years.

After a company presentation by the CEO Lars Willi, the Indian delegation appear enthusiastic about the state-of-the-art water purification systems but put off by the hefty price tag.

Even the CEO’s arguments that the quality and durability of the machines would make it an economical investment in the long run did not convince the Indian executives. It all boiled down to the high initial investment for a “Swiss quality” product.

“This is a very high end product in its present form. If it works out to be cheaper by reducing the durability, the benefits will be much more for the developing world,” Srikanth Vaidya of the Indian Oil Corporation told swissinfo.ch.

This is not the first time Trunz’s CEO has heard this argument.

“People in emerging markets like India would rather go for something cheap and buy something new after a while instead of investing in quality upfront and benefitting from it over five to ten years, he says.

In the beginning, Trunz had hoped to sell its mobile water purification units to international aid organisations but found out that they were reluctant to invest in new technology. The company was then forced to target the government sector where cost often overrules quality.

The reluctance of emerging markets in Asia to pay a premium for Swiss quality could hurt Swiss SMEs that rely heavily on exports. According to the Swiss International Entrepreneurship Survey 2013External link, on average 56.2% of SME turnover in 2012 resulted from export.

Asia alone represents around 21.8% of all Swiss exports according to 2013 data from the Swiss Directorate General for Customs. This number is expected to increase.

“Many Asian markets offer Swiss SMEs an immense export potential, with their growing middle class and rapid urbanization,” Wolfgang Schanzenbach, Regional Director Asia Pacific at Switzerland Global Enterprise (SGE) told swissinfo.ch. “We expect the easier to access Europe to keep its importance whilst Swiss exports to Asia are going to grow.”

According to the SGE’s fourth quarter SME Export Indicator for 2014, 54% percent of Swiss SMEs intend to export to the Asia-Pacific region over the next six months, more than even North America (48%).

Asia is also an important part of the internationalisation strategy of Swiss SMEs. On average, almost half of the Swiss SMEs surveyed have a presence in price conscious Asia, once again overtaking North America.

Cost of quality

Swiss SMEs are only too aware of the quality versus price dilemma. According to their responses in the 2013 Swiss International Entrepreneurship Survey, the price of their products and services was the most frequently cited (41% of the 788 Swiss SMEs surveyed) possible obstacle to internationalisation. This is much higher than other common obstacles faced by businesses like bureaucracy (second at 34.5%) and investment costs (third at 24.6%).

“The problem with selling Swiss products is that we develop them with a Swiss perspective but then realise in India that we do not need such a high level of quality, so many features or such long-term durability,” Roger Moser, director of the University of St Gallen’s Asia Connect Center told swissinfo.ch.

This is an area that Trunz CEO admits there is room for improvement.

“As with most Swiss companies, our initial approach was to find a technical solution and only later check its market potential. Some of our equipment might be over-engineered to a certain degree for Indian requirements,” he says.

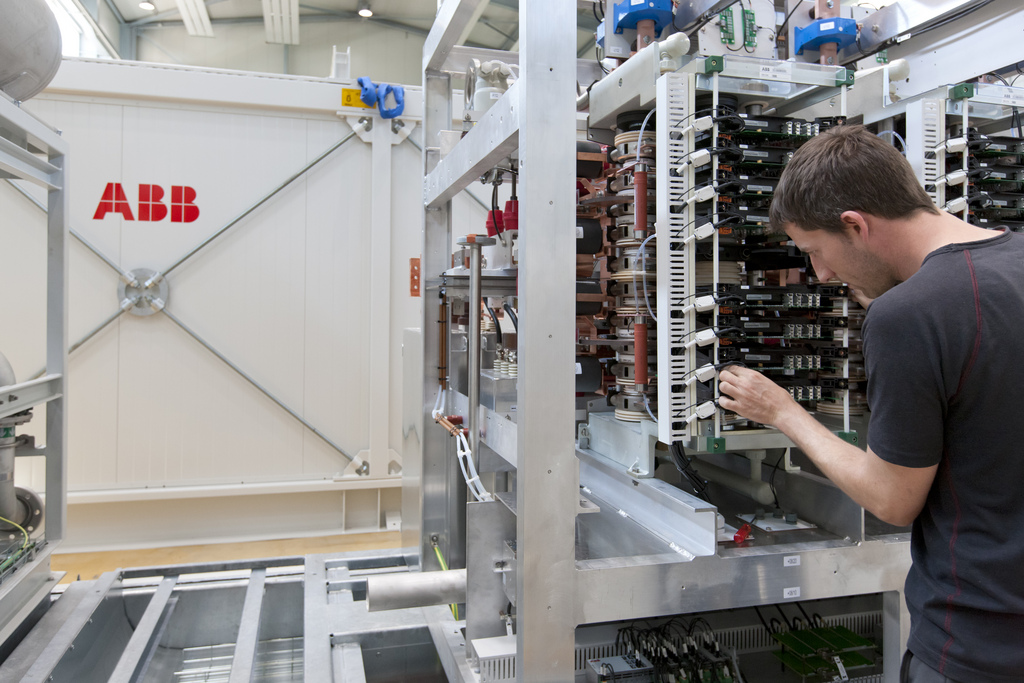

High Swiss labour costs are another issue. It is one of the highest in the world amounting to CHF61.3 ($65) per hour on average for the manufacturing and services sectors. Perhaps producing some of the components abroad could make Swiss products more accessible to emerging markets.

“A lot of engineering expertise is located in Switzerland but I agree that mid-sized companies have to be more open to doing some part of the development in India otherwise you miss the fit with the local requirements,” says Moser.

However, despite the potential cost savings, few Swiss SMEs have the resources to invest in new production facilities abroad.

“Shifting some production to India will save some money in terms of employee salaries and import duties but this would require significant investment in setting up a local manufacturing plant,” says Willi. “To recover this investment, we need to have a proven potential first and we haven’t seen that in India yet.”

Swiss brand

Besides practical issues there is also reluctance on the part of SMEs to risk damaging the “Swiss made” brand that is known and appreciated in developed markets. Almost a quarter of the SMEs surveyed listed exploiting the benefits of “Swissness” as a reason for internationalisation.

Swiss quality is something that Trunz takes great pride in.

“We stand for long-term reliable quality and innovative products. Our business card is a unit that works well for a long time without any intervention,” says Willi.

The visiting Indian executives also appeared to be aware of the Swiss “quality versus price” dilemma.

“It’s a call Swiss companies will have to make, whether they want to remain very elite with that Swiss tag or whether they can dilute it a bit by retaining Swiss know-how and technology but opting for outsourced hardware,” one of them told swissinfo.ch.

Diluting the Swiss brand is something Rico Baldegger, professor at the Fribourg School of Business Administration and author of the Swiss International Entrepreneurship Survey, strongly advises against.

“For the last 30 or 40 years we developed our brand image around quality. If we go in another direction we could have a quality problem with our products that could destroy our brand uniqueness,” he says.

Instead Baldegger recommends that Swiss SMEs should be prepared to change their market segment and even business model if necessary to find people who are willing to pay a premium for a quality product.

This is exactly what Trunz is currently doing.

“Now, we don’t just intend to sell the units but operate them and sell the water. In the end, we hope to finance ourselves not from the government but by local people, as we can produce clean water cheaply,” concludes Willi.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here. Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.