Maxon motors make Mars mission mobile

If small is beautiful, then the motors from a small company in central Switzerland can boast being that and much more.

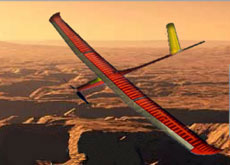

The tiny drive units from the maxon motor firm are not only small, but also powerful and have even found a niche for themselves on planet Mars.

Packed with technology and weighing in at next to nothing, the motors from Sachseln in canton Obwalden have performed vital roles on Nasa’s Mars rovers – Spirit and Opportunity.

The motors are used for driving the robotic arms, rock drilling, the steering mechanism, controlling the cameras and for the six high-tech wheels that drive the heavy rovers, each weighing nearly 180 kilos.

Still going strong

The rovers, which have been exploring different regions of Mars to find out more about its geological conditions, in April found proof that water existed on the red planet. They are still in operation and radio contact will continue until the mission ends in September.

maxon motors are no strangers to Mars because they were also used for the Sojourner rover in 1997.

The company was approached back in 1991 by a Nasa division, Jet Propulsion Laboratory [JPL], which was looking for motor manufacturers that could help it find a small, powerful package for that first mission.

“They approached maxon and asked us if we could develop a motor that could withstand temperatures of between minus 120 and plus 25 degrees Celsius,” the company’s head of overseas sales, Rolf Fergg, told swissinfo.

“It was then that maxon management decided to help JPL find a solution,” he added.

On the latest Mars missions, which began on June 10 last year, maxon motor provided 39 out of the 43 electromotors on each rover.

High efficiency

They are highly efficient, but that performance has a price, with maxon motors costing up to five times that of conventional motors.

“The maxon type of motor is definitely more expensive than a conventional type of motor. It’s based on the fact that we need more magnet material and the manufacturing of the winding is more complicated and therefore time-consuming,” Fergg explained.

The history of the company dates back to the 1960s when the German Braun company came to Sachseln to make parts for its electric razors.

From razors to motors

When Braun decided to sell the razor business to Gillette in 1967, the company had to find another product to survive.

“Finally, it was decided to develop, produce and sell small DC motors,” Fergg recalls.

The firm now has a staff of about 1,200 and manufactures about four million motors a year in a global market producing some seven billion.

The major business is with medical and laboratory technology, including battery-driven drills, infusion pumps and insulin pumps.

Other applications for the company’s motors are in construction tools, measuring and control technology, and they are even found in consumer goods, such as fully automated vacuum cleaners.

Maxon has hundreds of customers, who include such names as Siemens, Panasonic, Leica and Philips.

Nimble fingers

A look around the company’s factory in the idyllic setting of the Sarnersee brings one thing clearly to the fore. Most of the workforce are women and there is a good reason for that.

“About 40 per cent of the sub assembly is done by hand. The sizes of motors that we manufacture really require the fine hands of women to do the job,” Fergg told swissinfo.

“Men could simply not do it because they do not have the feeling for those small parts,” he added.

swissinfo, Robert Brookes in Sachseln

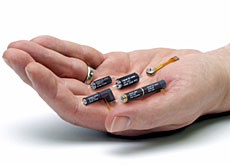

The “heart” of a maxon motor is the ironless winding, which has been patented worldwide.

With up to 90% the efficiency surpasses other motor systems by far.

maxon motor is a family stock corporation and had sales in 2003 of SFr176 million ($135 million).

Some production is also carried out at Sexau in Germany and at Veszprém in Hungary.

The planet Mars is exactly half the size of Earth.

Its days are 41 minutes longer and its axis leans 1.7 degrees more.

The seasons on Mars and Earth are similar but every season on Mars lasts twice as long.

The maxon motor company of Sachseln has provided 39 out of the 43 electromotors on each of the two rovers now exploring Mars.

The motors are standard products with diameters of 20mm and 25mm that were modified slightly to deal with the extremely harsh conditions on the red planet.

Some 17 maxon motors were also on the failed Beagle 2 mission of the European Space Agency.

The company makes about four million motors every year.

Turnover in 2003 was SFr175.3 million ($140.63 million), up by 16 per cent on the 2002 figure.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here. Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.