3D printing could meet rising demand for heart valves

If Swiss researchers have their way, artificial heart valves could simply come out of 3D printers in future. Switzerland's Federal Institute of Technology (ETHZ), along with South African company Straight Access Technologies (SAT) has developed a silicone replacement for the heart valves used today. However, it will take at least ten years before the custom-made artificial heart valves can be used.

Heart valves ensure that the blood only flows in one direction. If they are leaky, constricted, dilated or even torn, the blood runs back, which puts a heavy strain on the heart. Cardiac arrhythmias or heart failure can occur in the worst-case scenario, writes ETH Zurich in a press releaseExternal link.

Experts expect that in the coming decades the demand for artificial heart valves will increase sharply in large parts of the world. This is due to ageing, lack of exercise and poor nutrition. Replacement heart valves from the 3D printer could help meet this demand.

Tailor-made replacement

The new silicone model, which researchers announced in the latest issue of the science journal “Matters”, has several advantages over the replacement flaps currently in use. These implants are mainly made of metal parts or animal tissue.

The flap can now be tailor-made. The researchers first determine the individual shape and size of the leaking valve and then create a computer simulation with which they can calculate the forces and deformations acting on the implant.

Saving time and money

Manufacturing artificial heart valves has so far been expensive and time-consuming, notes the report. For example, manual production takes a few working days. A flap from the 3D printer only takes about one and a half hours to manufacture.

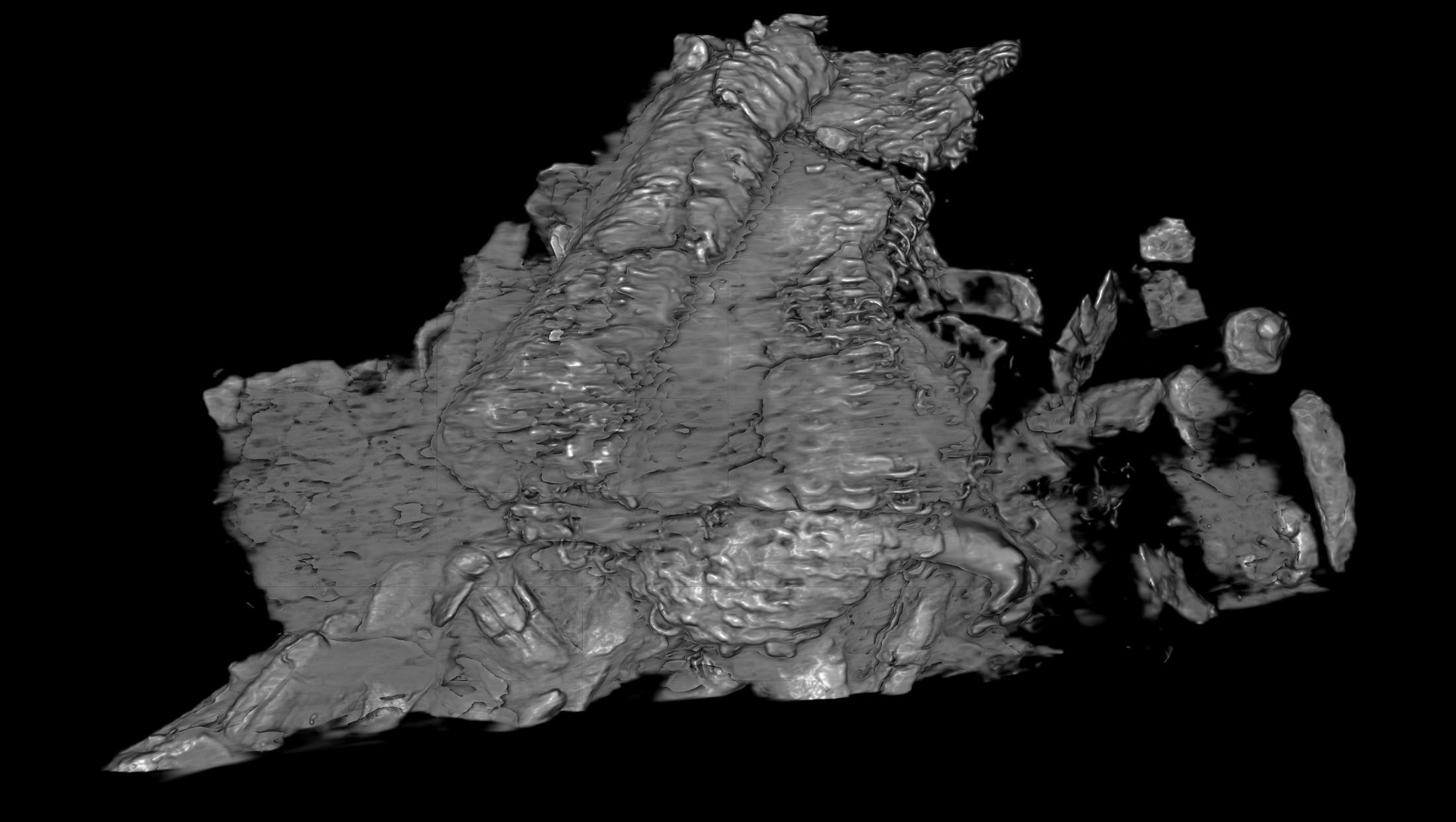

The scientists start by create a negative impression which has the shape of a three-pointed crown. Silicone ink is sprayed onto this, resulting in the thin flap wings. In a further step, a pattern of thin threads is printed onto the surface with tough silicone paste. These correspond to the collagen fibres that run through the natural heart valves.

The same procedure is used to create the blood vessel root connected to the valve, writes ETHZ. Finally, it is covered with a net-shaped stent, which is necessary for connecting the replacement valve to the bloodstream.

According to ETHZ, the first tests were very promising. The aim of the materials researchers is now to increase the service life of such replacement valves to 10 to 15 years. That’s how long the current models will last. However, it will take at least another ten years before the artificial silicone valves can actually be used. The products still have to go through numerous clinical trials.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here. Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.