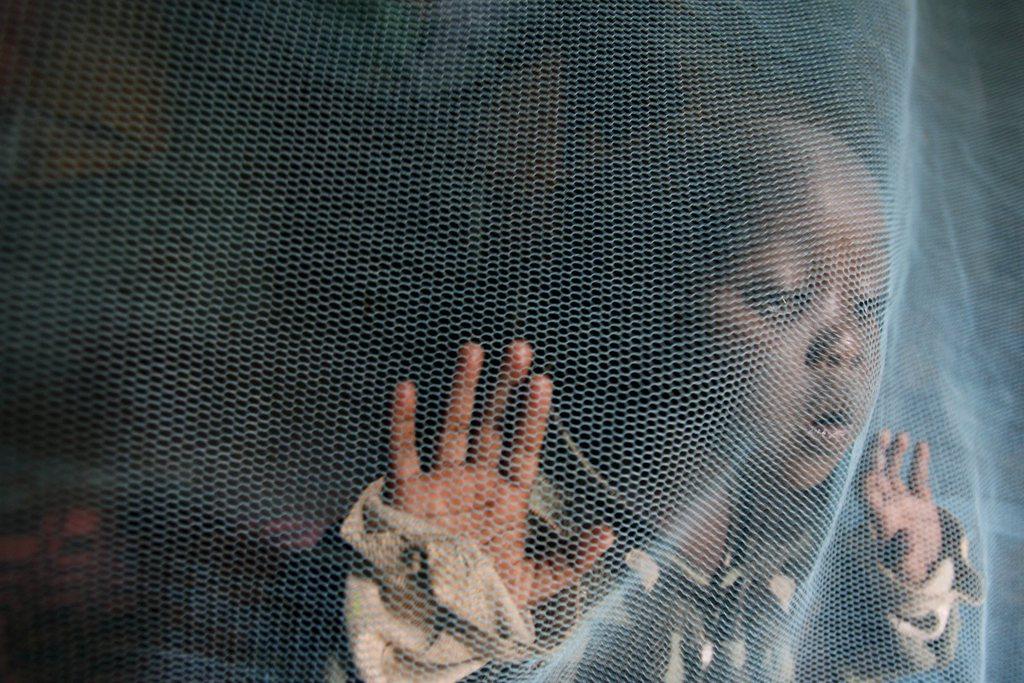

Net makers afforded scant protective cover

Global market can make life tough for local manufacturers.

Logic would suggest that A to Z Textile Mills is a company in the right place at the right time. This family-owned enterprise on the western outskirts of Arusha in northern Tanzania is one of the largest makers of long-lasting insecticidal bed nets in Africa, where 90 per cent of such nets are found.

Yet, despite being nearer to the main market than most of its competitors and a buoyant demand, Kalpesh Shah, one of the directors, says the company in the past year had to lay off almost 600 of the 4,500 staff who make the nets. This is thanks to fierce competition with companies manufacturing elsewhere in the world, particularly east Asia.

The majority of the world’s mosquito net business is funded by donors such as western aid agencies. But most offer tenders based on the price at the point of dispatch from the factory without taking into account delivery costs, which are borne by manufacturers. Mr. Shah says A to Z would “have some sort of parity” if donors considered overall costs. “We have to import all of our raw materials and so we’re always going to be expensive [at the point of dispatch].”

More

Financial Times

External linkThe Global Fund to fight Aids, Tuberculosis and Malaria does have a tender process that “uses delivery to market prices”, it says. “This is more effective and cost-efficient for the Global Fund and the people who will receive the nets. Procuring nets close to where they will be used means we save money on shipping costs and delivery is much faster.”

Since the Global Fund introduced market delivery tenders in 2012, A to Z has won “the largest portion of the tenders for the Global Fund for bed nets worldwide”, it says. But, despite this, the company says it is still losing out.

Mr. Shah says A to Z, which claims to have started with a single sewing machine five decades ago, made almost 25 million nets in the past year, about a sixth of the demand in sub-Saharan Africa. Most were delivered to east and southern Africa, places where, because of the factory’s location, it is competitive on an overall cost basis. The cost of doing business in Africa, however, means manufacturers such as A to Z cannot compete entirely equally. “Distribution costs to west Africa are higher from Tanzania than Vietnam,” he says of the south-east Asian nation, which is also one of the world’s leading producers. “This demonstrates the challenges of doing business in Africa and why more manufacturers are not based here.”

A steadily more crowded marketplace is making life tougher. Since 2010 the number of manufacturers of World Health Organization-approved nets has risen significantly, to the extent that annual global output capacity is more than 300 million. Aid agency tenders – which comprise the majority of demand – total about 60 per cent of that.

Indeed, A to Z, which also makes agricultural bags, garments and plastic products, only started manufacturing bed nets thanks to a corporate social responsibility partnership with Sumitomo Chemical. It began with a transfer of technology pilot project in 2003. Five years later this progressed into a manufacturing joint venture, even though both companies conduct marketing operations individually and sometimes compete for tenders.

Adam Flynn, a Sumitomo strategic communications and marketing manager, admits: “African manufacturing wouldn’t be an accountant’s first choice.

“But, with our corporate and social responsibility ethos, we’re taking a long-term view,” he says. “We think we have a moral duty to Africa and it has the skills and a rich textile heritage.”

In addition to the nets made by A to Z, Mr. Flynn hails the social, economic and indirect health benefits that accrue from manufacturing in Africa. For example, he cites the jobs that have been created at A to Z – most filled by women – as another way of helping to fight diseases such as malaria.

“Look at the millennium development goals and the sustainable development goals,” he says. “They talk about [lack of] development being a big part of why global health epidemics survive.”

While most manufacturers do not have factories in Africa, they do have research facilities on the continent. Swiss-based Vestergaard, one of the world’s biggest producers, says it is not economically viable to manufacture nets in Africa but has a laboratory at the University of Ghana.

Helen Pates Jamet, head of entomology at the company, says it is “crucial to maintain a strong presence on the ground, both by being able to access the right mosquitoes and building capacity in Africa to address capacity gaps”.

She says products developed at the laboratory are tested and used by staff and their extended families.

The good news for manufacturers such as A to Z is that, although more countries are moving towards elimination and eradication of malaria, demand for nets is not likely to abate soon.

“In order to cement the progress that has been made nets are going to continue to be necessary for many years,” Ms. Pates Jamet says. “And even if there wasn’t malaria, people still like to sleep under a net to keep mosquitoes away.”

Copyright The Financial Times Limited 2016

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.